At Konrady Plastics, we’re always looking for ways to deliver more value, speed, and innovation for our customers. That’s why we’re excited to announce the launch of our 3D printing services, expanding our capabilities beyond traditional machining to help customers move faster from concept to component.

Expanding What’s Possible

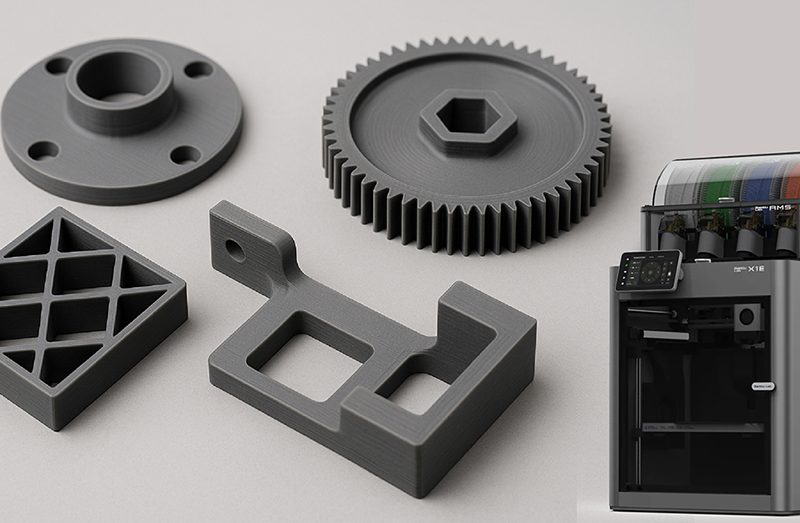

We’ve recently added the Bambu 1XE PF001-E to our lineup of equipment. This advanced unit features:

- Multi-color and multi-spool capability – can run up to 4 colors or spools at a time

- Generous build volume – 256mm x 256mm x 256mm (10.1” x 10.1” x 10.1”)

- Wide range of materials – Carbon/Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA

Currently, our team has successfully produced parts using PLA and Nylon PA12, and we are actively expanding into other materials to give customers more options for both prototypes and functional components.

What This Means for You

With in-house 3D printing, Konrady Plastics can help you:

- Prototype faster – Test designs, fit, and function before committing to full-scale machining

- Reverse engineer parts – Send us your component and we’ll create a digital model for printing

- Customize with ease – Experiment with geometries and lightweight designs that are difficult to machine

- Accelerate speed to solution – Minimize lead times with rapid prototyping and short-run production

Built on Reliability and Service

We know that speed and quality are critical. To keep production reliable, our team is also investing in spare extruders and material inventory—ensuring we’re ready to deliver without downtime in case of equipment issues.

Ready to Print

Whether you need a one-off prototype, a small batch of parts, or support in designing a solution that’s not possible through traditional machining, Konrady Plastics now offers 3D printing services to help bridge the gap.

Contact our team today to request a quote. Let’s bring your ideas to life—fast.